Applications of Nanotechnology in the Automotive Industry

Share

Introduction :

The automotive industry is increasingly incorporating nanotechnology to improve vehicle durability and reduce fuel consumption. Innovative coatings protect bodywork, while nanotechnology lubricants optimize mechanical performance.

Topic covered :

- Protective coatings for vehicles

- Nanotechnology lubricants for better efficiency

- Long-term impact on the automotive industry

The Integration of Nanotechnology in the Automotive Industry

Introduction

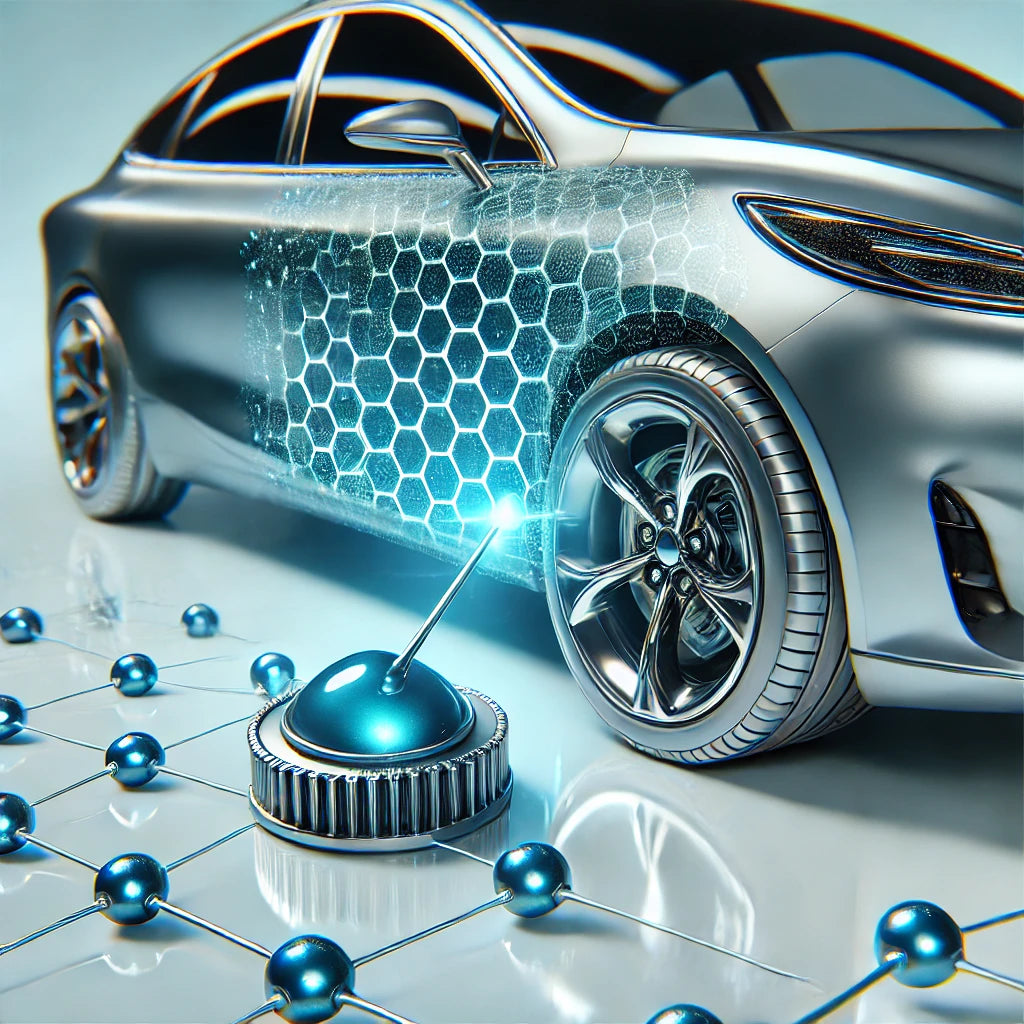

The automotive industry is rapidly evolving with the integration of nanotechnology. These advances offer significant improvements in durability, vehicle protection, and mechanical efficiency. Innovations in protective coatings, as well as nanotechnology lubricants, are increasing the strength of car bodies and optimizing fuel consumption, while reducing wear on mechanical components. This article explores how these innovations are transforming the automotive industry in the short and long term.

Protective Coatings for Vehicles

Ultra-resistant coatings

Protective coatings for vehicles have benefited from the introduction of nanoparticles, such as titanium dioxide, nanopolymers, and graphene. These materials offer unmatched properties in terms of protection against scratches, impacts, UV, and corrosion. Thanks to nanotechnology, automotive coatings have become thinner, lighter, and more effective in protecting the bodywork from the external environment.

-

Scratch Resistance : Nanoparticles give coatings increased resistance to micro-scratches that typically affect traditional automotive paints. This is particularly beneficial for vehicles used in urban or rugged environments where light impacts are common.

-

Corrosion Protection : Nanotechnology coatings also provide a protective barrier against corrosive elements, such as water, salt, and chemicals, which is essential for preventing rust, especially in areas with humid or salty climates.

-

Self-Cleaning Properties : Nanoparticles also allow vehicles to benefit from self-cleaning properties. By creating a hydrophobic surface, water and dirt slide off easily, reducing the need for washing and maintenance while maintaining the vehicle's aesthetics in the long term.

Heat Reduction

Some nanotechnology coatings are designed to reflect heat, reducing the absorption of solar rays by the vehicle body. This can help keep the interior of the car cooler, reducing reliance on air conditioning, which can improve overall fuel efficiency.

Nanotechnological Lubricants for Better Efficiency

Optimization of Mechanical Performance

Engine efficiency largely depends on the lubricants used to reduce friction between moving mechanical parts. Traditional lubricants work well, but they have limitations in heat and wear resistance. This is where nanotechnology comes in with improved lubricants based on nanoparticles.

-

Friction Reduction : Nanotechnology lubricants contain ultra-fine nanoparticles (such as graphene or metal nanoparticles) that significantly reduce friction between engine components. This friction reduction helps improve vehicle fuel efficiency, increase performance and extend engine life.

-

Temperature and Wear Resistance : Unlike traditional lubricants, nanotechnology lubricants are more resistant to extreme temperatures. The nanoparticles form a protective layer that prevents wear of mechanical parts even under intense operating conditions, which helps reduce wear and reduce maintenance requirements.

Improved Fuel Consumption

By reducing friction and improving the fluidity of lubricants, engines can operate more efficiently with less effort, which helps reduce fuel consumption. Vehicles equipped with nanotechnology lubricants can therefore travel more kilometers per liter of gasoline, which is particularly beneficial at a time when fuel economy is a global priority to reduce greenhouse gas emissions.

Long-Term Impact on the Automotive Industry

Energy Saving and Emission Reduction

The impact of nanotechnology innovations on the automotive industry is considerable. By increasing engine efficiency and reducing fuel consumption, nanolubricants directly contribute to reducing carbon dioxide (CO2) emissions, a key factor in combating climate change. In addition, nanotechnology coatings help extend the life of vehicles, reducing the need to produce and recycle new materials.

-

Increased Vehicle Durability : Nanotechnology protective coatings help extend the lifespan of cars, especially in harsh environments. This means vehicle owners can use their vehicles for longer without the need for frequent repairs or replacing expensive parts, reducing the overall cost of ownership.

-

Towards Advanced Automation : In the future, nanotechnology could play a vital role in developing smarter, more autonomous vehicles. Nanotechnology sensors, for example, could be integrated into vehicle monitoring systems to detect even the slightest changes in mechanical performance or road conditions, increasing safety and efficiency.

Evolution of Materials

Car manufacturers are investing heavily in nanotechnology materials research to develop new, lighter, stronger, and more environmentally friendly automotive components. Graphene, for example, has the potential to be used not only in lubricants and coatings, but also in batteries, bodywork, and structural elements of vehicles.

-

Vehicle Weight Reduction : By using lighter nanomaterials, manufacturers can reduce the overall weight of vehicles, resulting in better fuel economy and increased performance. Materials such as graphene and nanotech composites could replace heavy metals traditionally used in automotive construction.

-

Battery Innovation : Nanomaterials, such as lithium nanoparticles, also enable the development of more efficient batteries for electric vehicles. These batteries could have faster charging capacity, increased energy density, and longer life, contributing to the mass adoption of electric vehicles.

Conclusion

The integration of nanotechnology into the automotive industry is revolutionizing the way vehicles are designed, manufactured, and maintained. Protective coatings extend the life of vehicle bodies, while nanotechnology lubricants increase engine efficiency, reducing fuel consumption and environmental impact. In the long term, these advances will contribute to a more sustainable and efficient automotive industry, while paving the way for even more exciting innovations in materials, energy management, and vehicle safety.